Drowsy eyed and half Awake we boarded the bus at 5:00 am to head to Parma. I slept 90% of the way so I couldn’t tell you much about the drive. We arrived at the Parmesan Cheese Artisan. This family run production was just starting the process for eight rounds of Parmigiano-Reggiano.

The steps to make this cheese are:

1. Selecting the milk – the cows are given a strict natural grass and vegetable feed diet to keep them healthy and happy. This facility milks 150 cows daily. Once in the morning and once at night.

2. Separating the cream- the milk from the night milking goes into a basin where it’s is left to separate over night. The cream rises to the surface and is removed and used for butter. The non-fat milk is then used in the morning batch and that same day’s morning milk from milking is added to create a semi-fat mixture. It takes 4.23 gallons of milk to make 1 kg/2.2 lbs of Parmesan.

3. The cauldrons- the semi fat mixture is poured into a copper steam jacketed kettle. Steam is then pumped into kettle to hear the milk.

4. Adding Whey – after warming up a natural whey (the lactic acid ferments from the cheese the day before) is added to the milk. (Rests for 25 minutes)

5. Natural Rennet- this natural enzyme is added to cause the milk to curdle (an enzyme taken from a calf stomach lining)

6. The Spino- a worker manually breaks the curds with a round ball device called a Spino.

7. Heating – the milk is then slowly heated while being agitated by a machine. Once it’s heated to the proper temperature the heat is turned off. The kettle sits for an hour to let the curds settle.

8. Removing and Casting – after and hour two men use sacks and a machine to remove the cheese. The original weight is 90kg removed then it is sliced in half so each plastic form holds 40 kg. the cheese sits in the plastic mold for 2 days. This cheese is turned 3x a day.

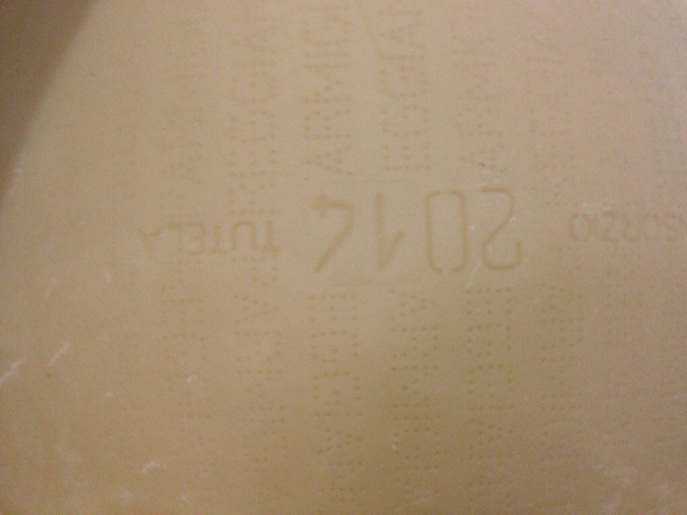

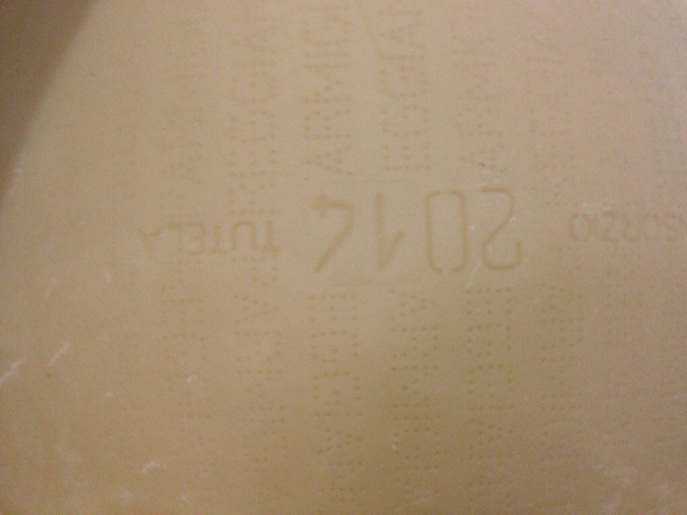

9. Marking- on the second day the cheese is put in a metal cast and a plastic brand is wrapped with it. The wrap contains the date and year created, the company number, and the certificate number.

10. Salting – after a day of marking the cheese is removed from the metal cast and placed in a salt brine. It sits in the brine for twenty days to absorb the salt. This salt adds flavor and helps the aging.

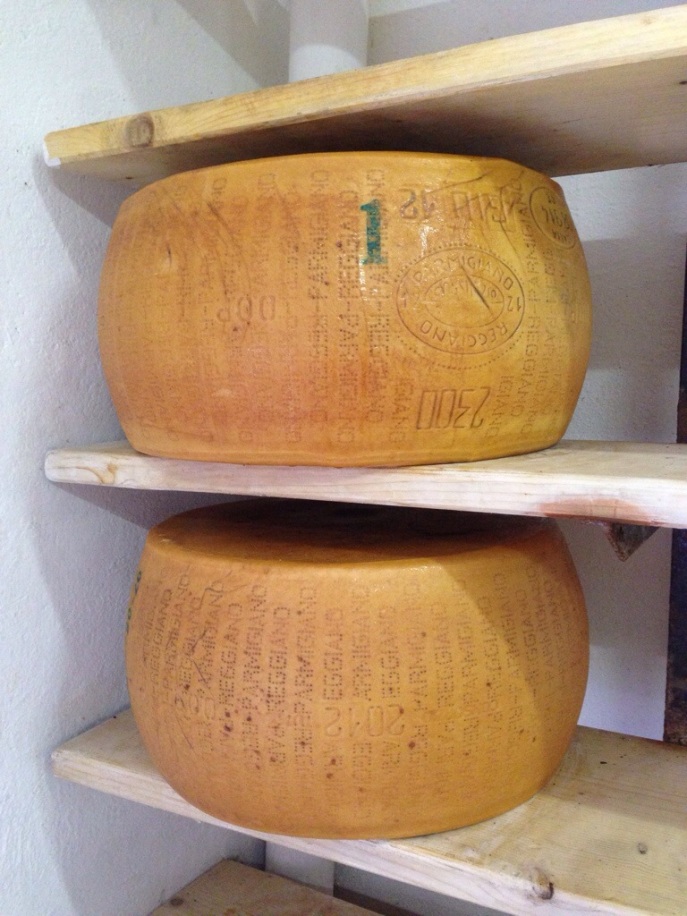

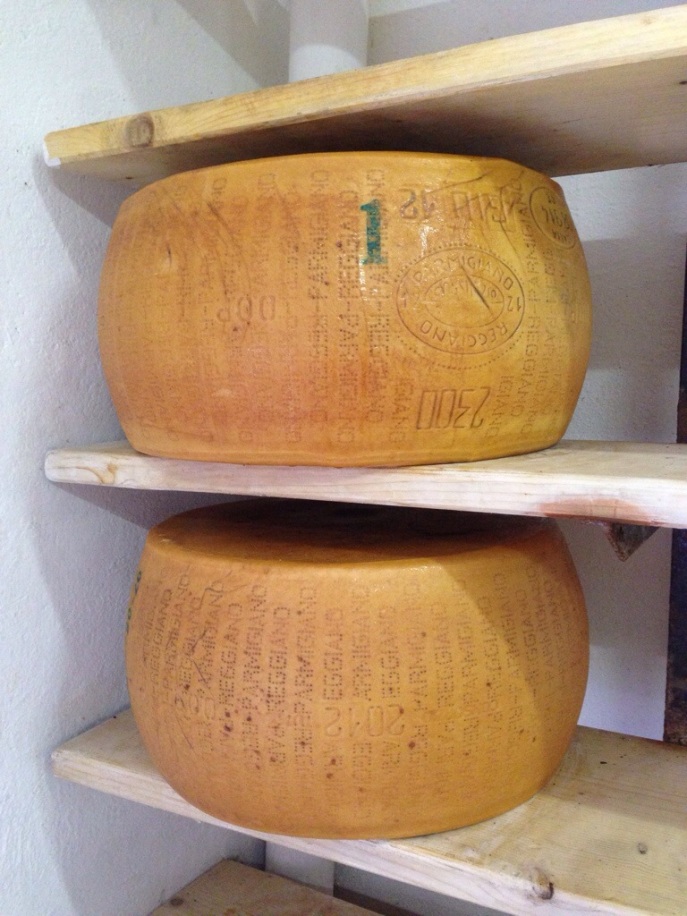

11. Aging – the cheese is removed from the brine and set on a shelf in a temp controlled room for a minimum of 24 months

A cheese wheel is inspected at 1 year if age. The inspector taps the cheese with a hammer and listens for holes and odd sounds. If the cheese passes it is branded “Parmigiano-Reggiano Consorzio-Reggiano”. This brand means the cheese can continue to age for an additional year or two. A Parmesan wheel cannot be aged longer than 3 years if they want to have a good product. If it’s is not well enough to continue aging but a good product, lines will be drawn through the brand. They also earn a DOP brand if the meet the specific procedures and produce in Parma, Reggio Emilia, Modena, and specified parts of Bologna.

A cheese wheel is inspected at 1 year if age. The inspector taps the cheese with a hammer and listens for holes and odd sounds. If the cheese passes it is branded “Parmigiano-Reggiano Consorzio-Reggiano”. This brand means the cheese can continue to age for an additional year or two. A Parmesan wheel cannot be aged longer than 3 years if they want to have a good product. If it’s is not well enough to continue aging but a good product, lines will be drawn through the brand. They also earn a DOP brand if the meet the specific procedures and produce in Parma, Reggio Emilia, Modena, and specified parts of Bologna.

She then explained about the recycling they do with the products. The liquid left over from production is fed to their pigs to make them high in natural proteins. Like the olive oil artisan they are searching more ways to reuse all of they waste they produce.

Other fun facts:

1.Parmesan cheese that completely fails inspection is sold as Granna. This is usually what big industry mixes with a small amount of real Parmesan and treats with chemicals to give it a longer shelf life.

2. 1 wheel of Parmesan is=

40 kgs and sells for 500 € each!

3. 1kg of cheese is made from 16 L of milk. This cheese has a very High concentration of milk per kg.

After seeing this whole process we got to taste some cheese. We tasted 1, 2, and 2.5 year aged wedges of their cheese. My favorite was 2 years, but I thing the 2.5 would be great shredded. They also served us their ricotta which they make on thursdays in their facility. They had us try it with black cherries (fantastic combination) and on a coconut cake (not my favorite but it was a nice combo).

It was very interesting to see this process and here the passion in the daughters voice about what her family does. All of our tour guides have been so passionate about their products and it is very inspiring. Next post you will see how prosciutto is made!

The first step is to salt the fresh leg and hang it in the first fridge at 3 C at 80 % humidity. After it all sets the meat is run though a wash to remove the salt and is massaged to tenderize it.

The first step is to salt the fresh leg and hang it in the first fridge at 3 C at 80 % humidity. After it all sets the meat is run though a wash to remove the salt and is massaged to tenderize it. The meat is now darker and it is salted again and hung in a new fridge at 2 C for two weeks. After the process of removing the salt and massaging is repeated.

The meat is now darker and it is salted again and hung in a new fridge at 2 C for two weeks. After the process of removing the salt and massaging is repeated.

Lastly the leg moves to the last, 12 C, room where it is washed and then hung for 2 months. At the end the leg is pricked with a porous bone and smelled by experts. The experts brand the leg giving it approval.

Lastly the leg moves to the last, 12 C, room where it is washed and then hung for 2 months. At the end the leg is pricked with a porous bone and smelled by experts. The experts brand the leg giving it approval.